Description

IMPELER OPTION

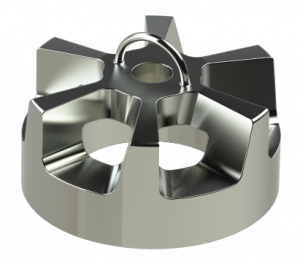

SMA

The SMA model features a patented flow channel design. During cleaning, the flow channels force cleaning fluid through the bearing area, providing very effective and repeatable cleaning results. SMA generates very low shear forces, which makes it ideal for applications with shear sensitive products, such as mammalian cell cultures.

With respect to mag mixer impellers, a closed impeller is one that must be submerged to be cleaned. As the impeller is rotating, centrifugal force is drawing the fluid into the area around the bearings. This fluid is flushed out the small holes in the top of the impeller.

SMO

SMO is an open design that exposes all surfaces to the cleaning solution just by means of directing flow from a spray ball to the impeller head. It is not necessary to submerge it during cleaning.

With respect to mag mixer impellers, an open impeller is one that can be cleaned during CIP by means of a spray ball action, without submergence.

SMMS

The SMMS design provides higher shear forces for applications where incorporation of light or hydrophobic powders is needed. The impeller is also an open design that does not require to be submerged during cleaning.